Set-up procedures for knives and anvils can vary according to the make and model of the packaging machine, knife adjustment style, and other factors. There are, however, some general principles that make these adjustments more effective and efficient, reducing downtime and parts costs.

♦ Optimize Knife Design

- Knives ground on a diagonal, or bias–whether they have a zig zag or a straight cutting edge—require less pressure to cut so they are easier to set up and typically last longer.

- Zig zag knives with smaller (more) teeth are also easier to set up and provide longer life.

♦ Set Up the Crimpers First

- Clearance and Pressure Adjustments required to create a good seal can impact the knife and anvil set-up.

♦ Make Sure the Crimpers, Including the Slots, are Clean Before Installing Knives and Anvils

- Material or product build-up can make parallel adjustment of the knives and anvils difficult or impossible, and may cause intermittent cutting issues during production.

♦ Always Change the Anvil When Changing a Knife

A knife may not cut cleanly across previously made impressions in a used anvil, and the excess pressure required to cut can cause premature knife failure.

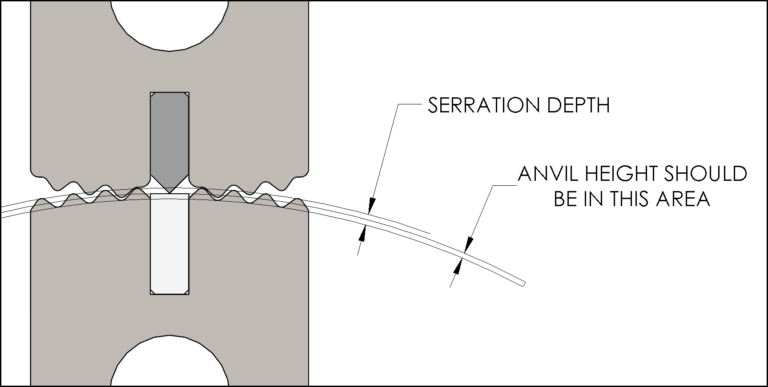

♦ Install the Anvil First, at the Proper Height

- To avoid damaging the crimpers and to optimize knife and anvil longevity, the anvil should be installed so that the working surface is at or slightly below the midpoint between the root and the crown of the serrations. The knife should then be adjusted out to cut.

♦ Use High Quality Shims

- Shims must be flat and free of burrs, which can cause uneven adjustment. Greener can provide precision shim stock in a variety of thicknesses.

- To create the most stable platform for knives and anvils use as few shims as possible (two .005” shims, for example, rather than five .002” shims).

♦ Remember That Temperature Can Impact Knife and Anvil Performance

- Allow newly installed knives and anvils to heat up before making final adjustments.

- Higher or lower temperature settings due to product or film changeovers may require a slight readjustment of the knife.

- The actual temperature of the crimpers, and the knives and anvils within them, is typically higher at set-up than during production, and temperature can change according to line speeds. These variations may affect cutting performance. (See our related post on Heat.)

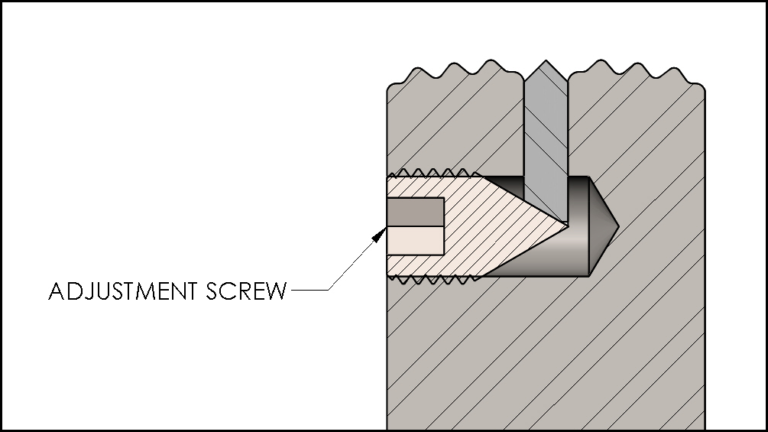

♦ Standardize Knife and Anvil Adjustment Style

- Both adjustment screws and shims are reliable methods for adjusting knives and anvils. Some people have a strong preference for one style over the other, based on their experience and level of familiarity.

- Though adjustment style is often dictated by the design of the crimpers installed when the packaging machine was purchased, packaging lines—even those with machines of different makes or models—can usually be retrofitted with new sealing jaws and knives that all utilize the same adjustment style. Standardization streamlines operating procedures and training, and can reduce inventory costs by decreasing the number of knife and anvil designs kept in stock.

Optimizing knife and anvil design and set-up helps these parts to last longer, reducing downtime and lowering costs. Improperly adjusted knives and anvils can also negatively impact seal quality—a topic that we will cover in future posts.

For additional technical support please contact Greener Corporation.