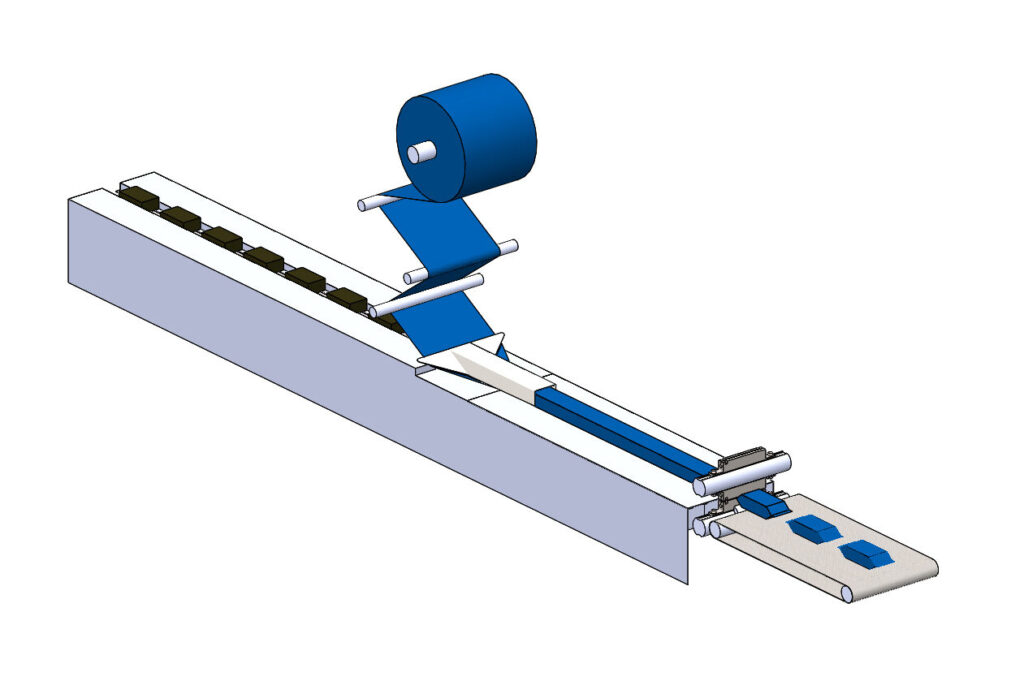

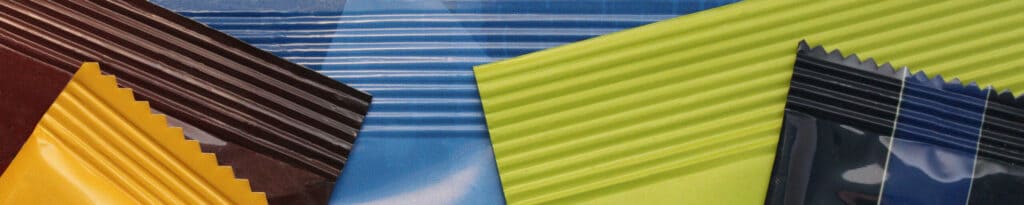

This Greener Corporation “Tech Bite” provides a Troubleshooting Checklist for working with us to solve packaging problems on horizontal flow wrappers. Answers to the checklist questions will allow us to help define your problem, determine the causes, and develop solutions that restore package quality and productivity.

With this video and blog post as a guide, you can start the problem solving process by contacting Greener Corporation. You may not have immediate answers for every question; just provide as much information as possible. Our technical staff will request any additional details that they need.

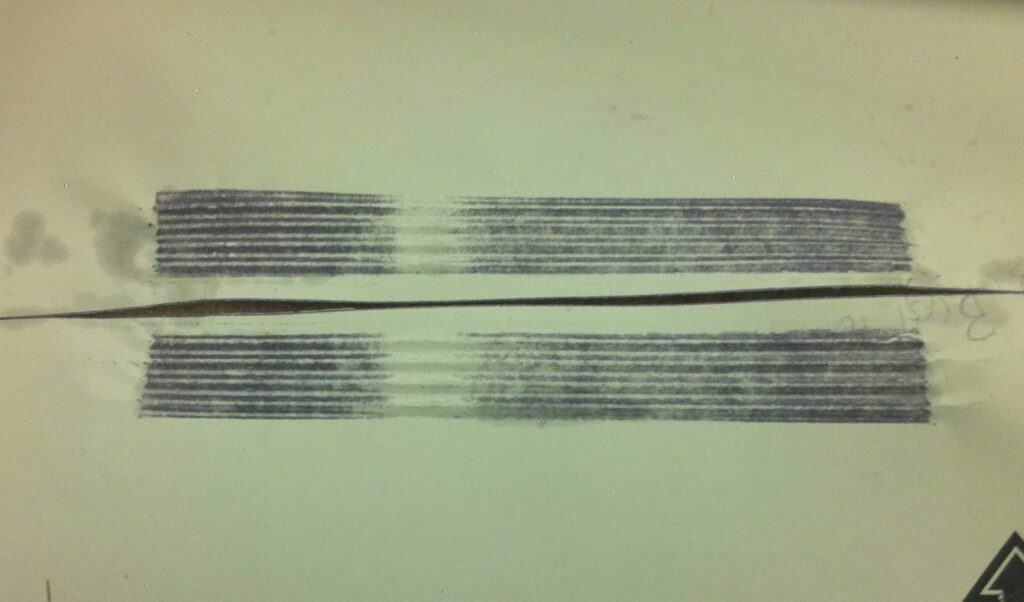

1. Define the Problem

Let’s further clarify when and where the problem exists.

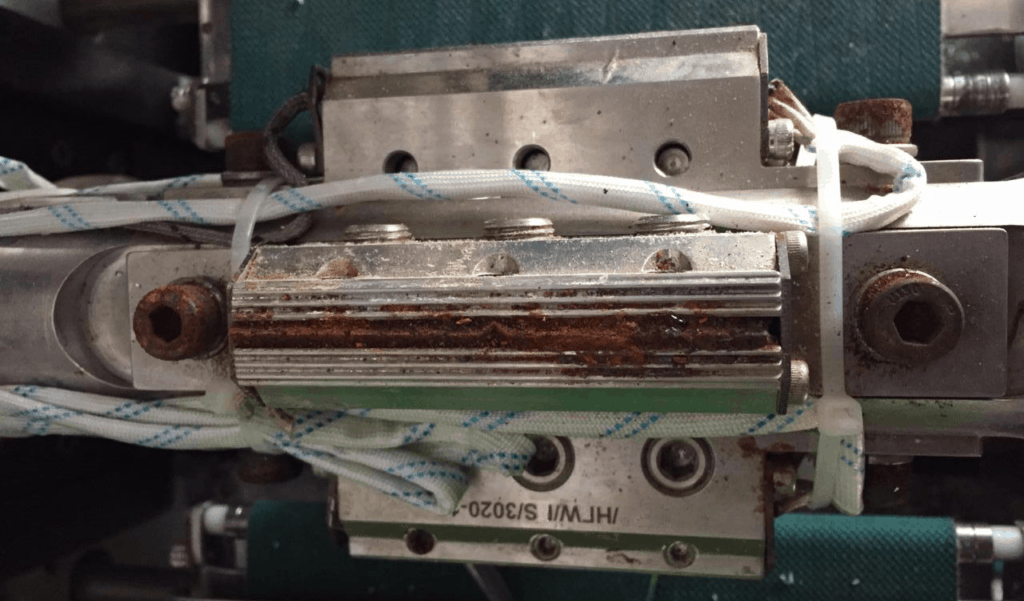

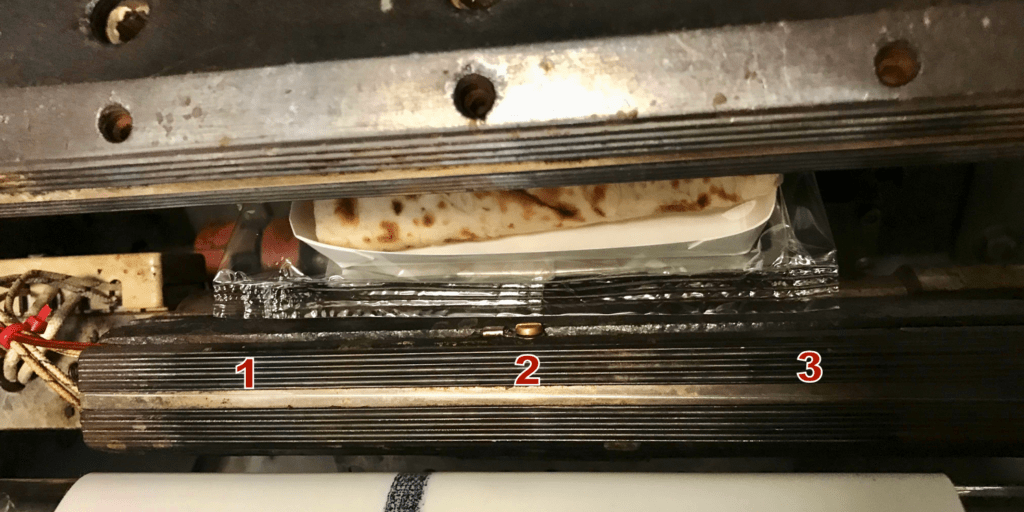

2. Determine Causes

3. Develop Solutions

Every detail, even those that seem insignificant, provides clues that will help us develop effective solutions to your packaging problems.

To initiate technical assistance contact Greener Corporation. We develop and deliver solutions worldwide.

This Greener Corporation “Tech Bite” provides a Troubleshooting Checklist for working with us to solve packaging problems on horizontal flow wrappers. Answers to the checklist questions will allow us to help define your problem, determine the causes, and develop solutions that restore package quality and productivity.